Die Casting Dies

Home » Die Casting Dies

Engineering and Consulting

From prototype to series production

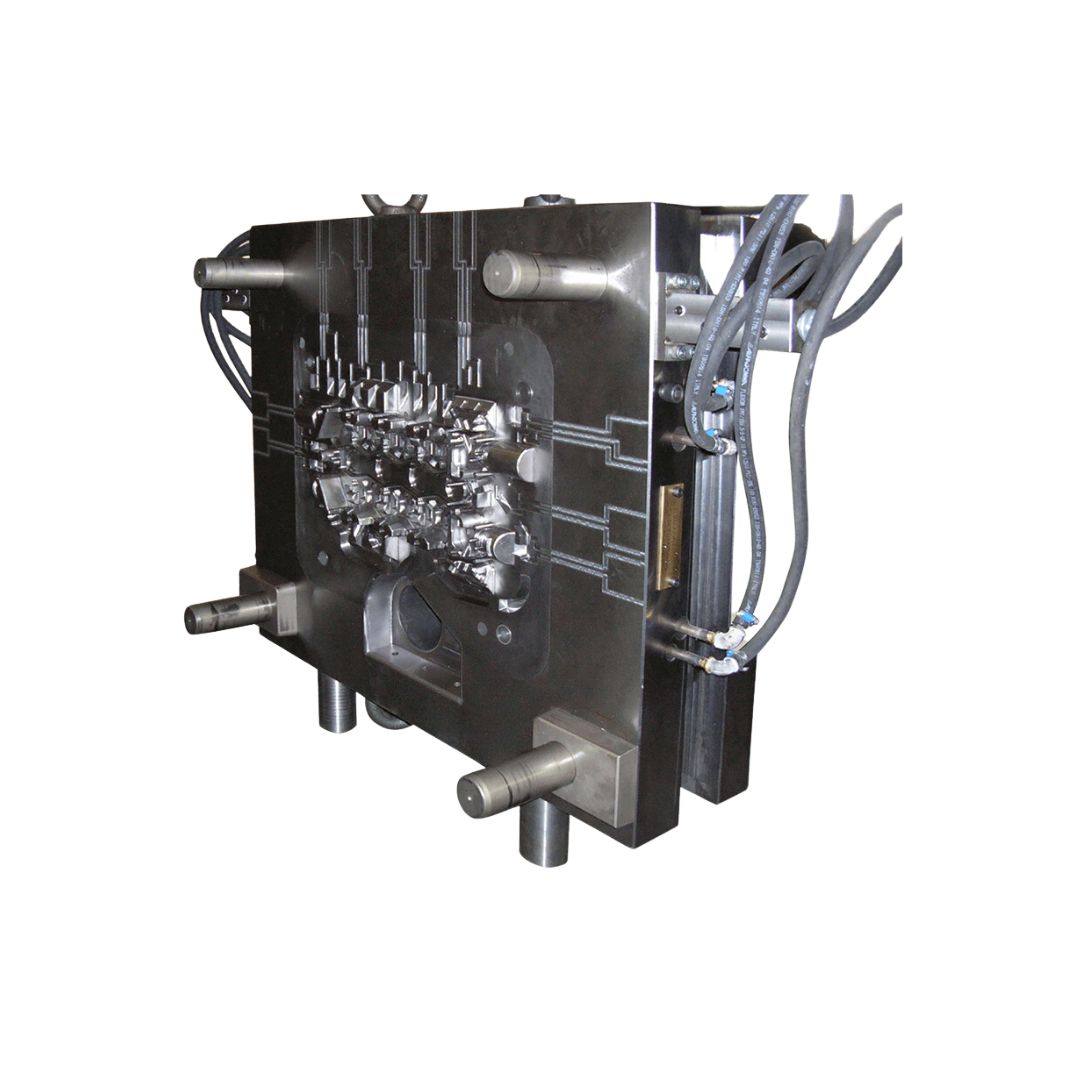

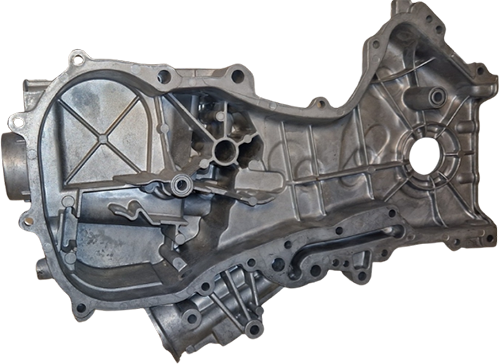

We are specialized in accompanying the customer in the transition from the prototype phase machined from billet or with additive manufacturing to series production (small or medium).

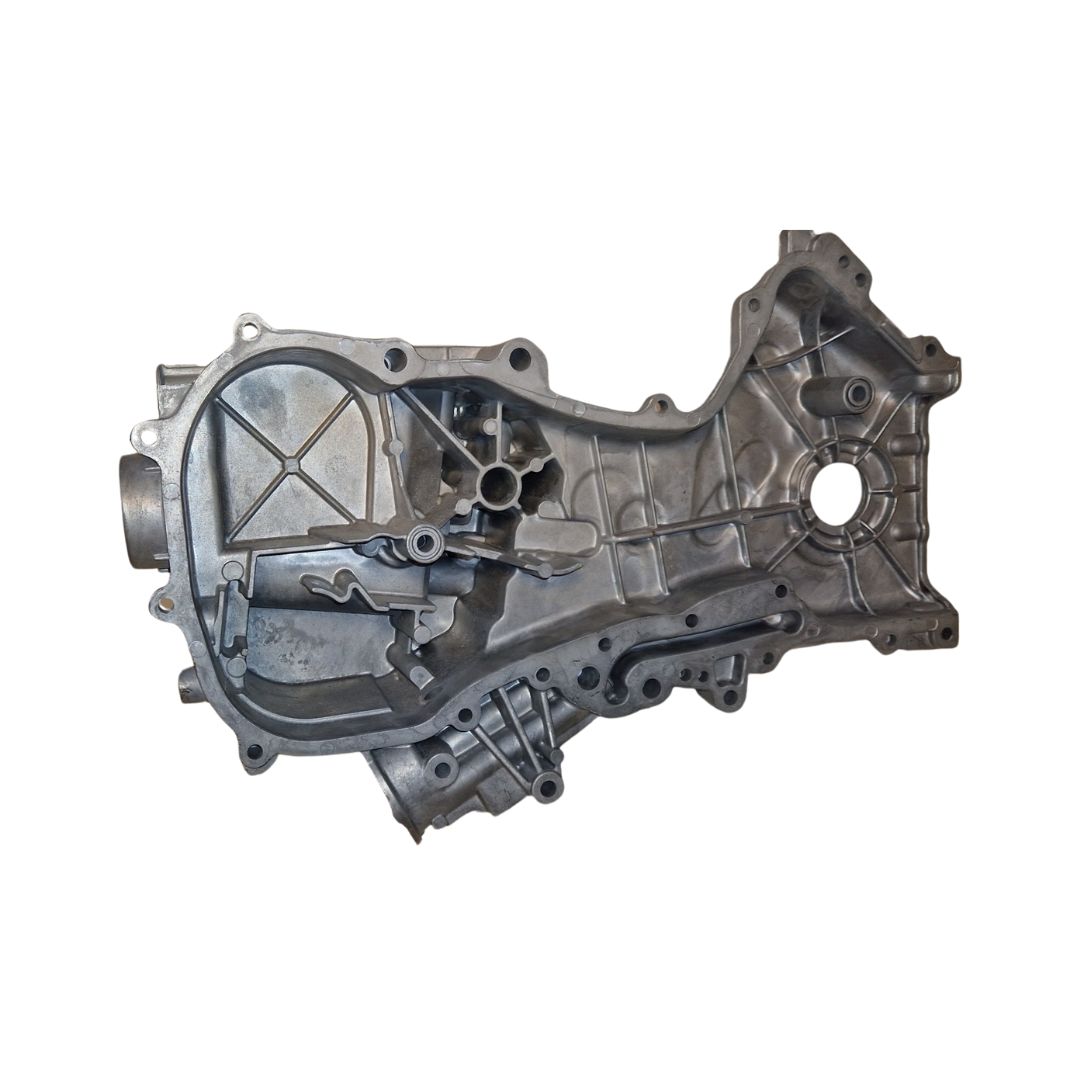

Based on the specific needs of functionality, quality, budget and production volume we collaborate in the DFM analysis of the casting, definition of the subsequent processes and development of the necessary equipment (mould, trimming tools and processing and testing jigs.

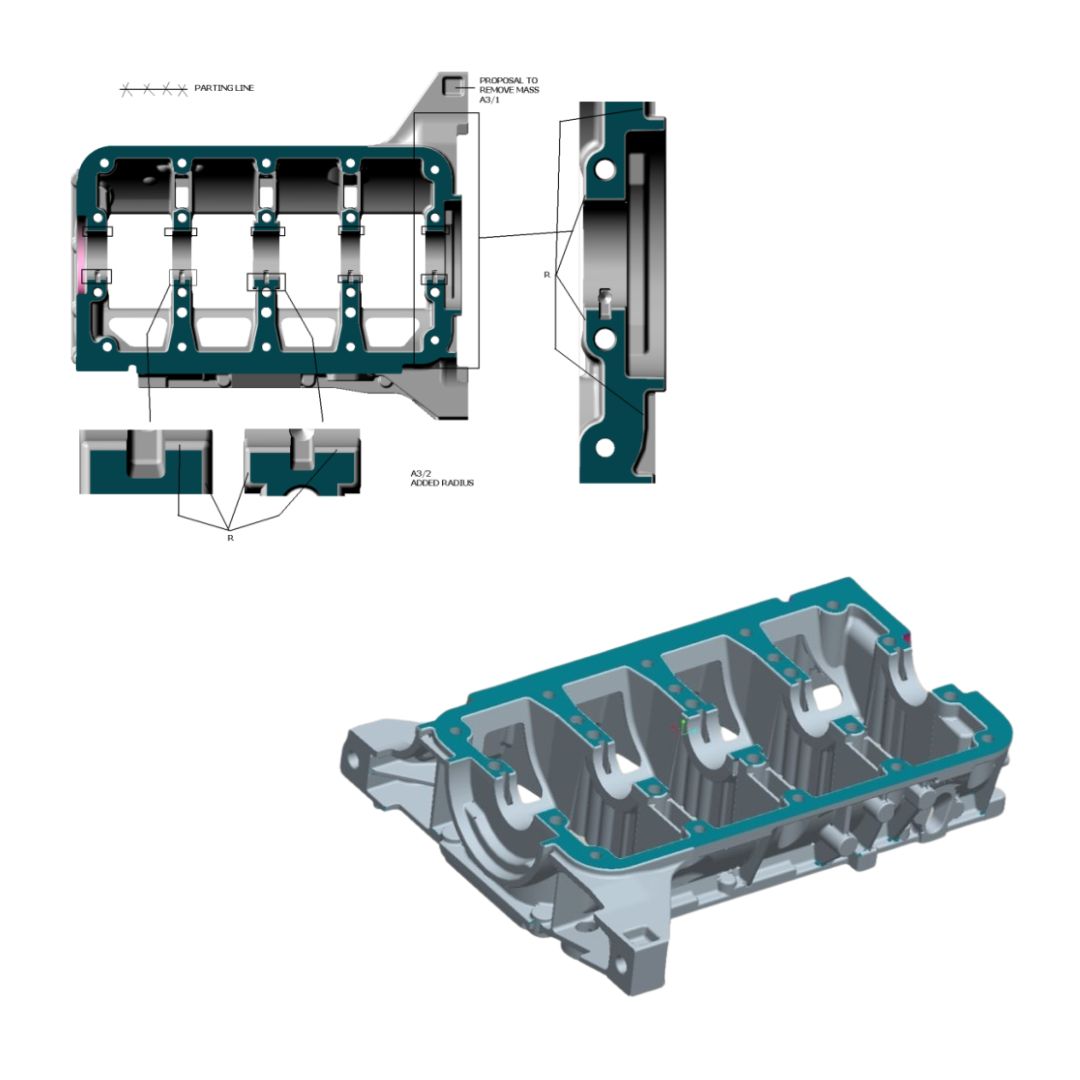

Product engineering and co-design

Taking into account the qualitative and economic requirements, the component design is structured for die-casting, collaborating with the customer to maximize the efficiency of the entire production process.

DFM

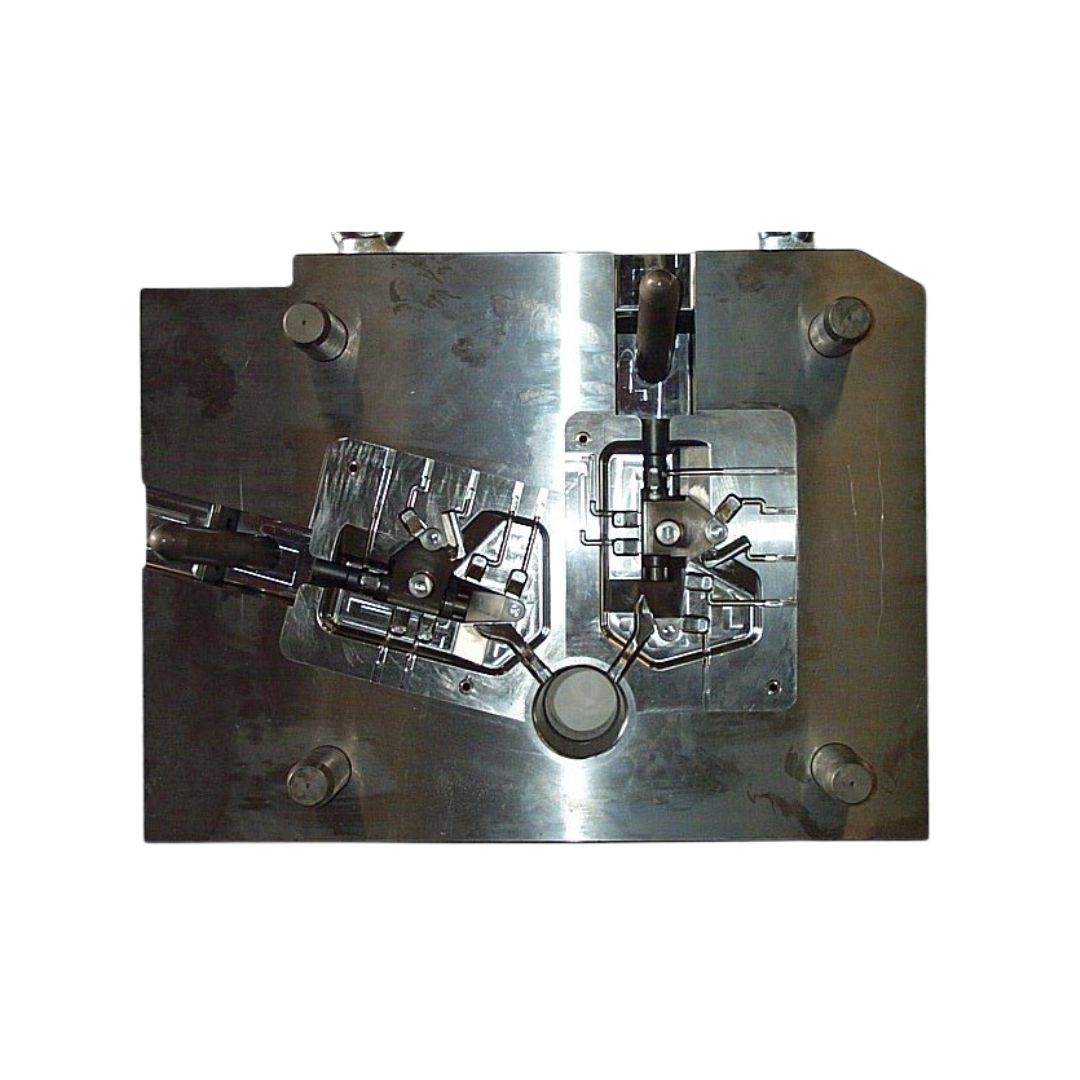

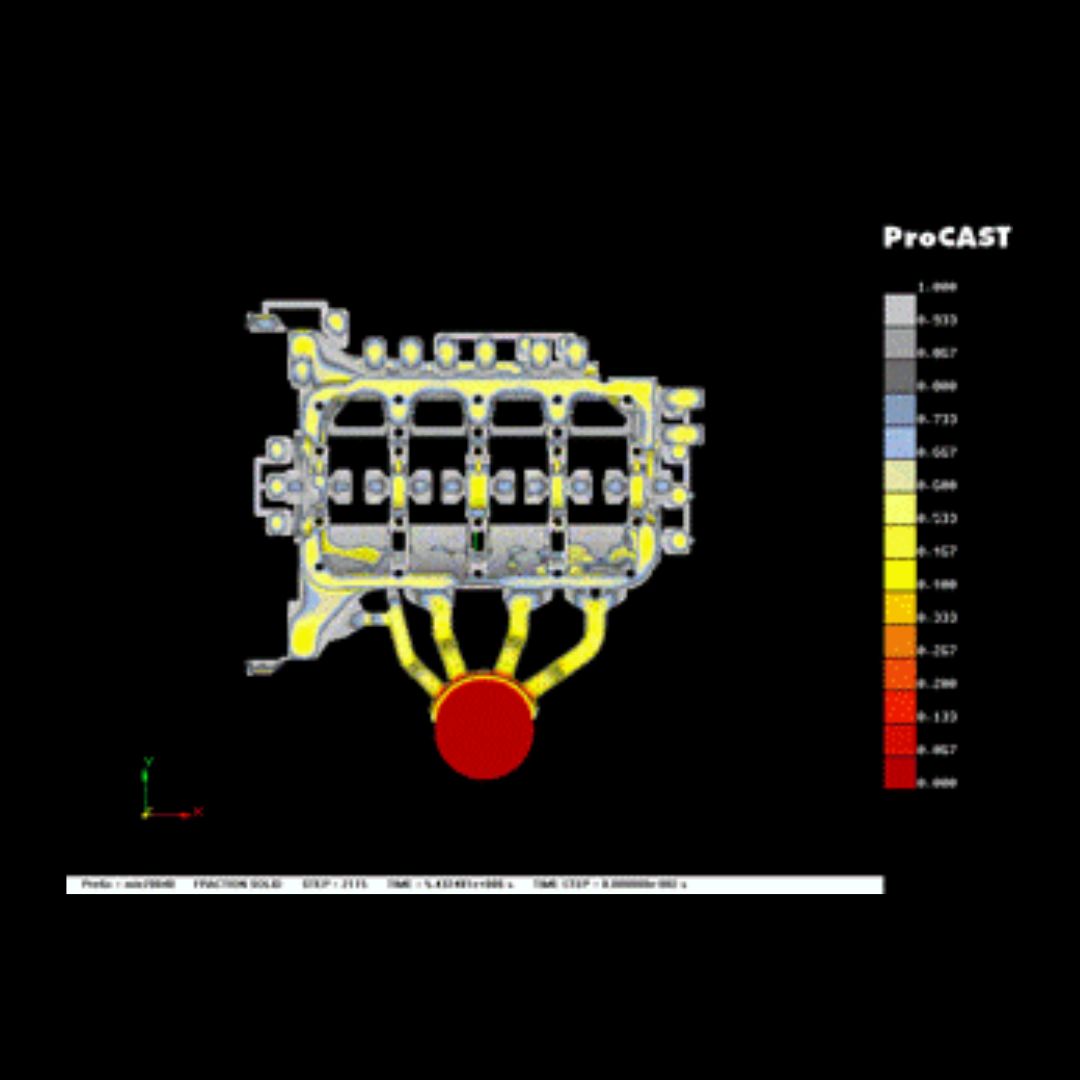

Design - Simulation

Tooling

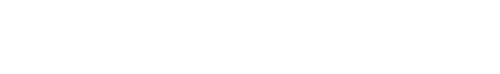

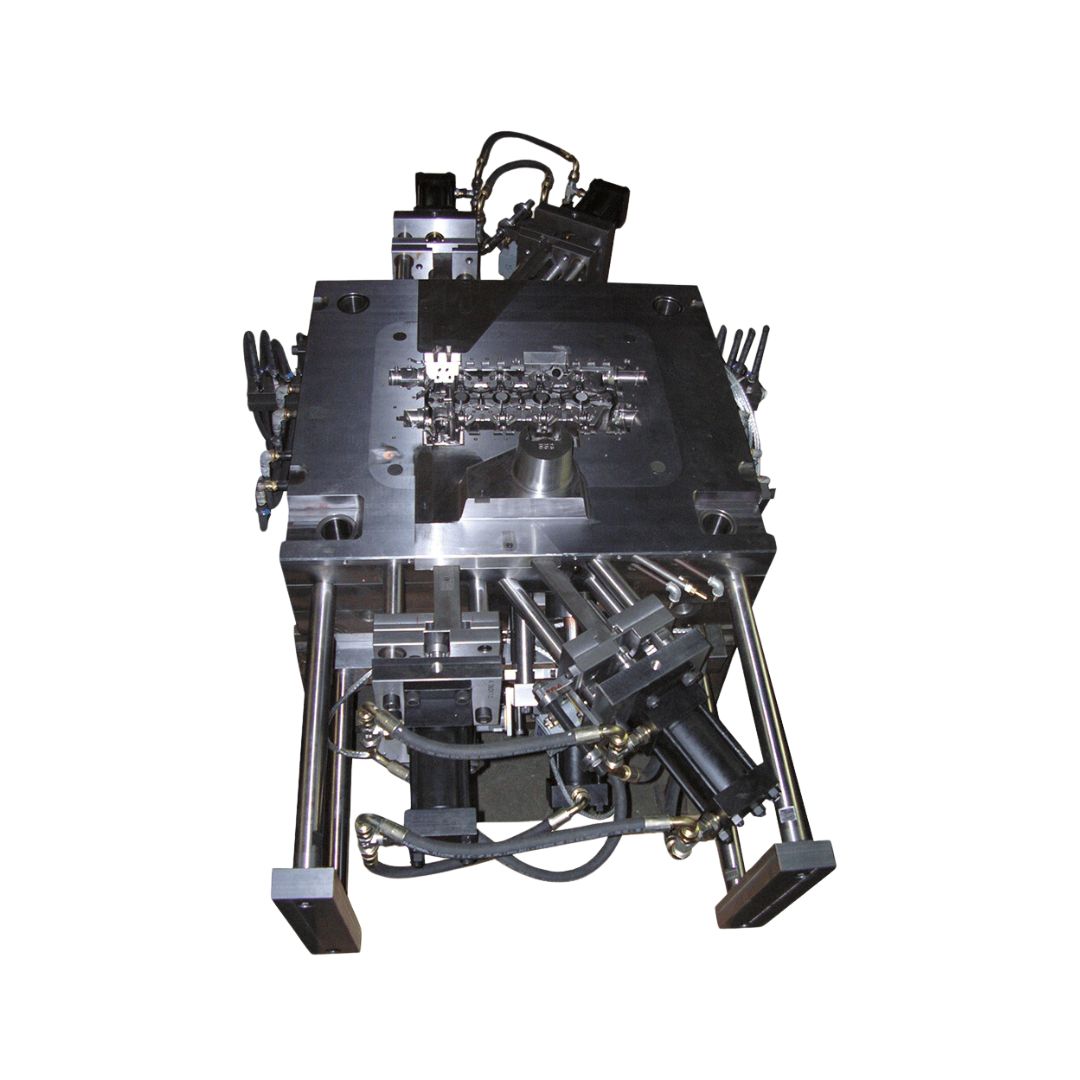

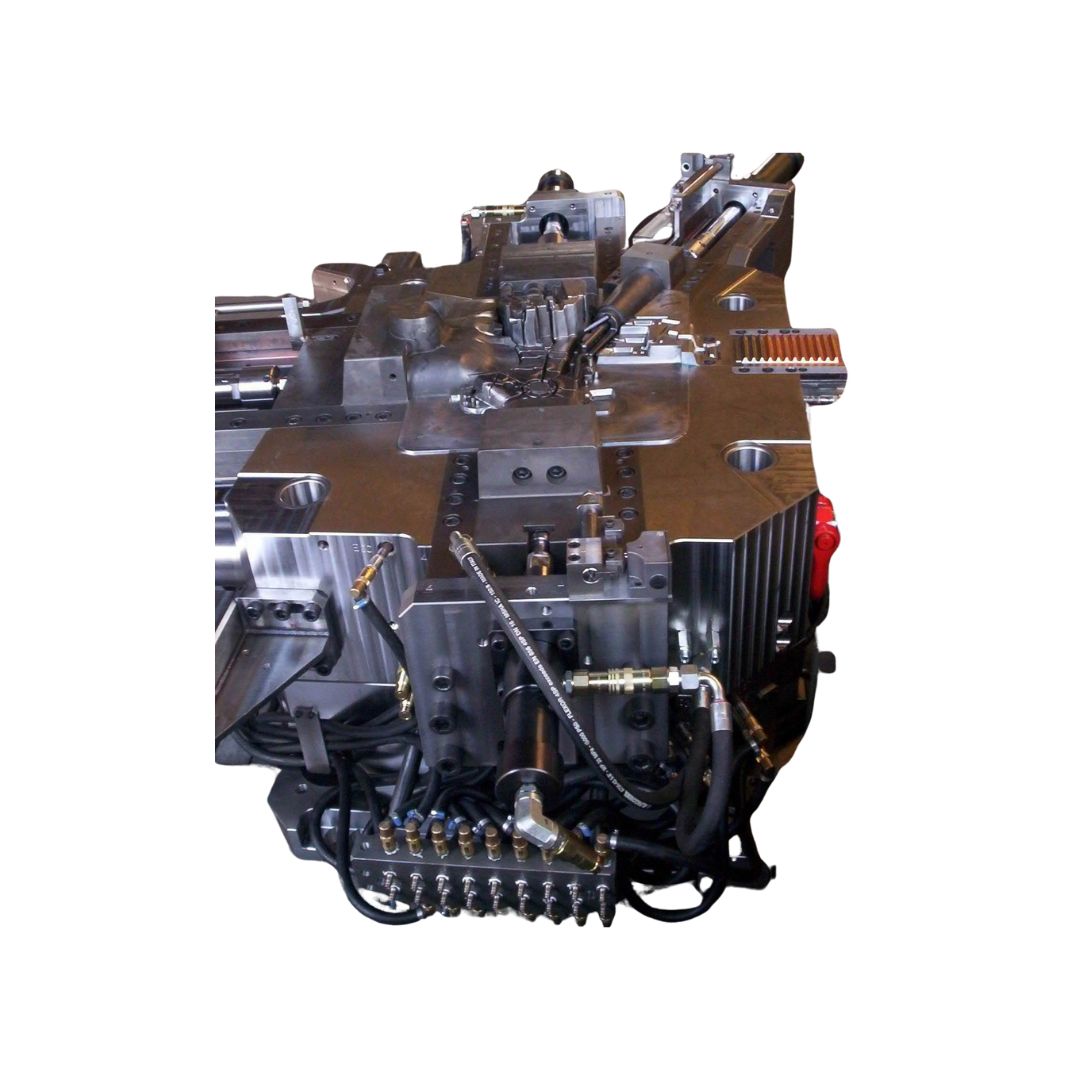

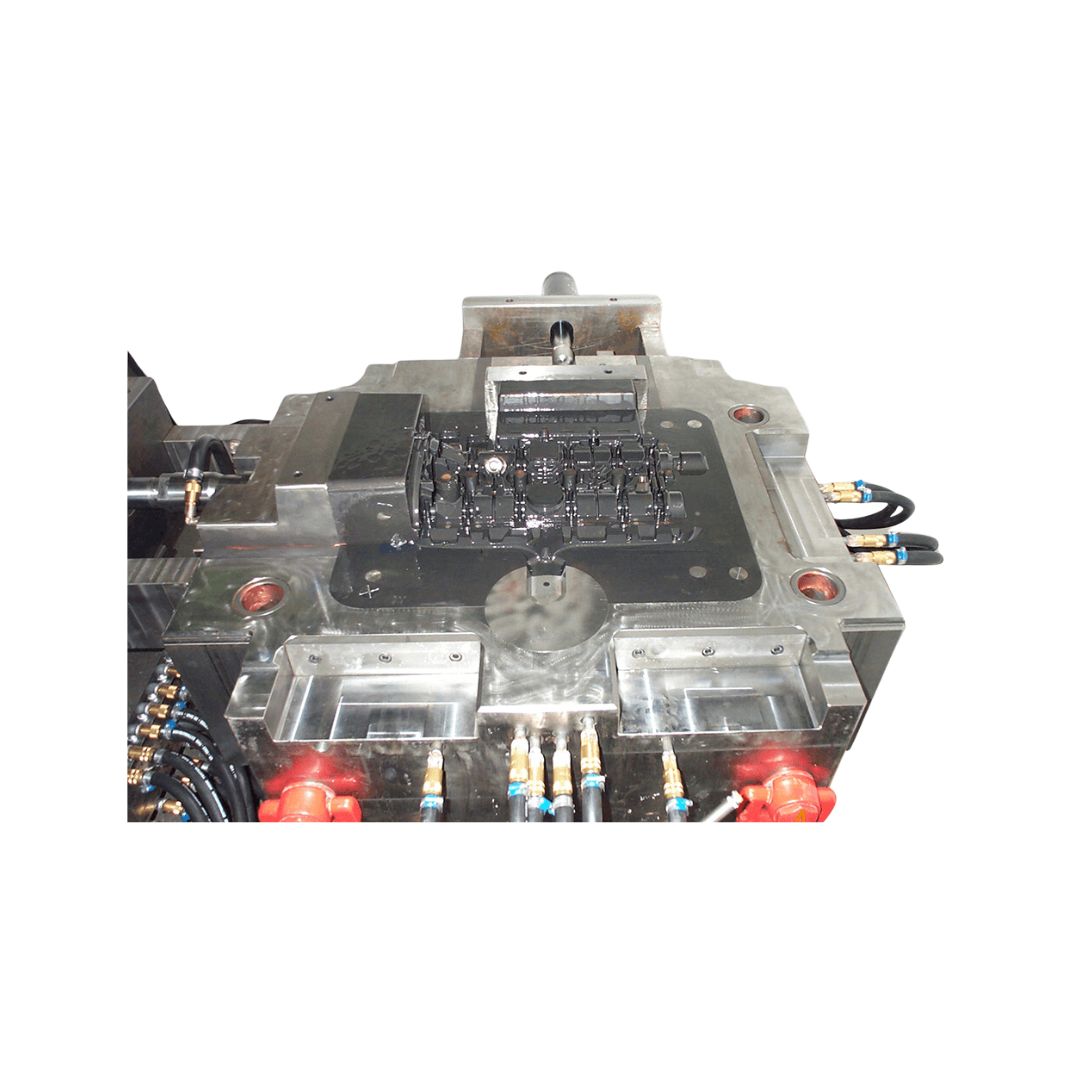

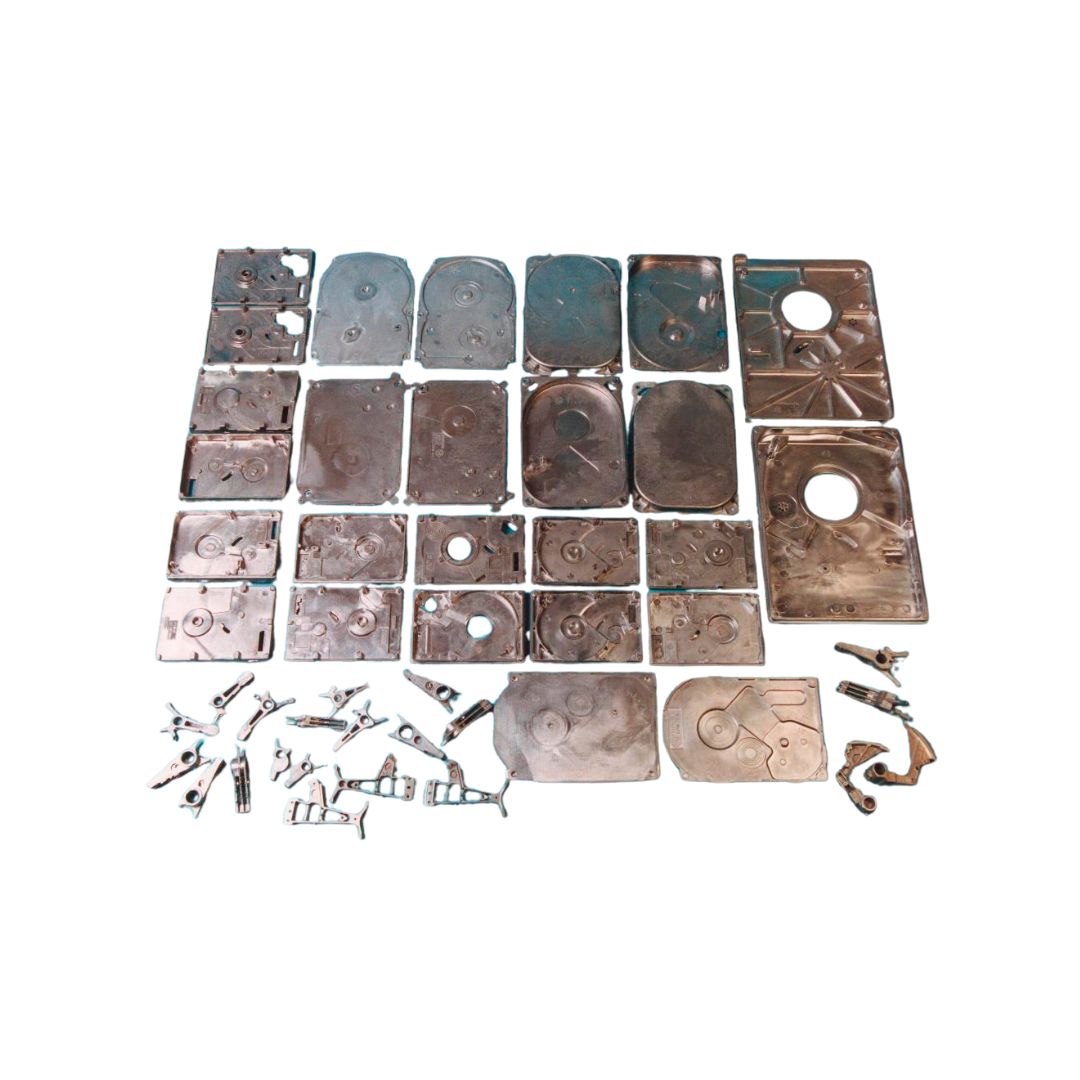

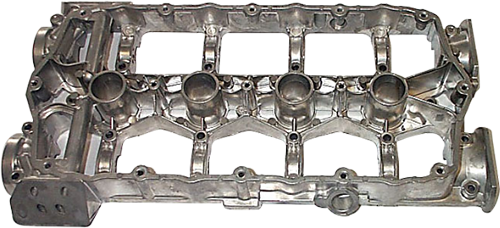

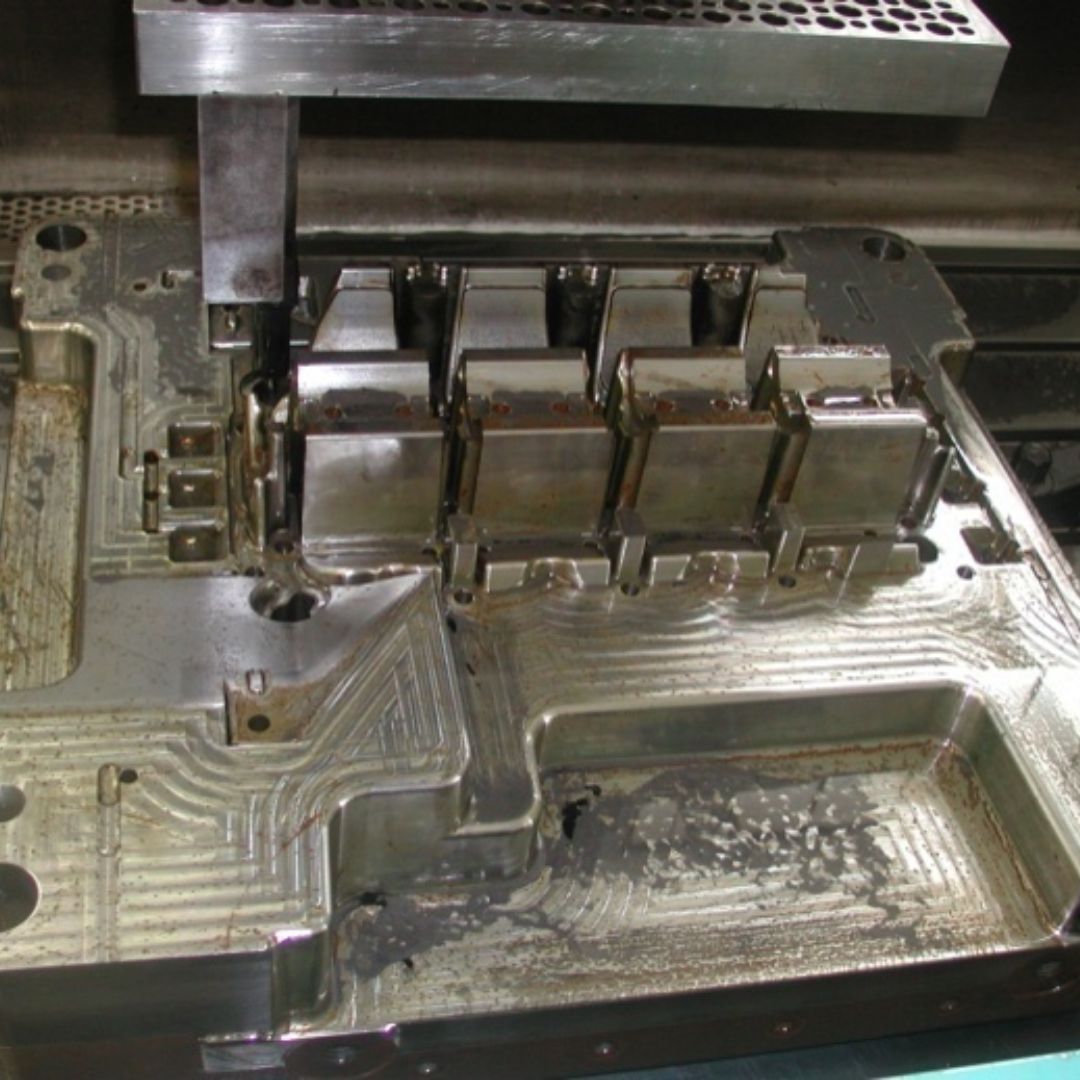

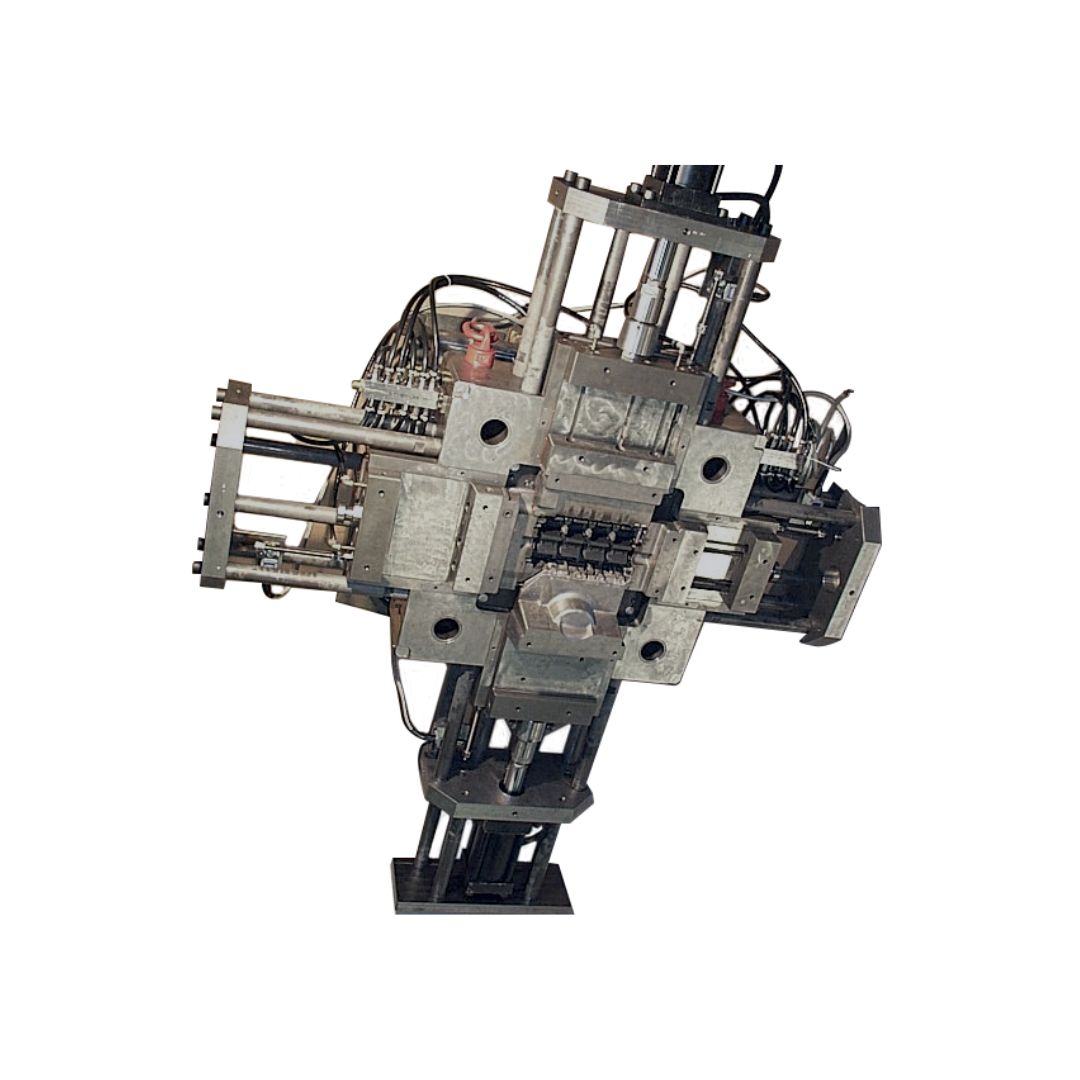

Die-casting die

Design, manufacturing and testing of high pressure die-casting dies

For over 40 years Matrix engineering has been designing, building and testing moulds for leading international foundries and for customers who entrust us with the production of their products.

The design and development of the mold are carried out with advanced CAD (CATIA V5 and SOLIDWORKS) and casting simulation programs.

For materials and treatments we use qualified suppliers with a solid tradition of quality.

We guarantee the equipment we supply for the expected lifespan and offer consultancy / follow up services to the customer.

Main sectors: Automotive, aerospace and defence, medical and Ho.Re.Ca.